Home » Blog » VFD industry » Variable speed drive energy saving in cement industry

Variable speed drive energy saving in cement industry

Variable speed technology has been applying in every kind of industries. A Shenzhen factory has applied variable speed drive in cement industry from 2012. At present, the variable speed drive is working on kiln back exhaust fans, high temperature fans, kiln head coal mill fans, kiln head surplus fans, raw mill circulating fans and so on.

Most of variable speed drives are applying on high temperature fans, kiln head coal mill fans, kiln head surplus fans, raw mill circulating fans and so on. Two production lines with daily productivity 5000T in the Cement factory. By variable speed drive, the two production lines achieve ideal energy-saving effect.

The shortcomings of original hydraulic couplers

Asynchronous motor adjusts speed by changing the supply power frequency of stator to realize variable speed adjusting speed. It can maintain small speed disparity during the process from low speed to high speed, so the small consumption speed disparity power and high efficiency is the most reasonable method of adjusting speed for asynchronous motor.

At present, the variable speed adjusting speed is main adjusting speed method for asynchronous motor; it is widely used in many fields.

Variable speed speed system has many significant advantages as following:

Taking variable speed drive on high-temperature fans for example: the production line of daily production 5000t, high-temperature fan motor is equipped with 6kV/2500kW variable speed drive.

According to the load parameters and operation condition provided by cement plant, the variable speed drive (rated voltage is 6kV, rated current is300A) is applicable to the plant.

Kiln-back high-temperature fans system introduction

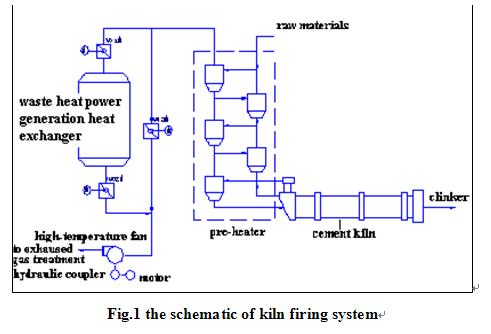

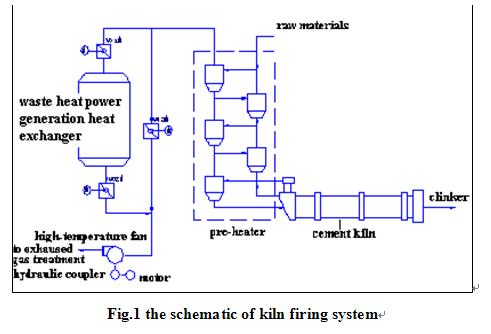

Cement Production line are hanging with kiln, its circuit system is shown as Fig.1.

Rotary kiln with daily production 5000t has heated steel cylindrical with 4 degree bevel, diameter of 4.8m and length of 74m, various firebrick were inserted in it. Raw materials from pre-heater enter the kiln from the back of kiln. It is mixed and calcined in rotary kiln at high temperature depending on the the kiln rotating, and materials move forward depending on the slope of the kiln and the kiln rotating.

Reconstruction introduction

The power and the heat diffusion of variable speed drive is much. In order to ensure adequate ventilation cooling, we designs wind duct on the top of variable speed drive cabinet and power cabinet respectively. They connect to outlet as a whole, discharging the heat outside, ensuring the reliable ventilation effect.

The statistic of energy saving

We make statistic about the related operation data before and after variable speed drive reconstruction. The part of the data are analyzed and collected as follows:

1) The comparison table between cement no.1 and no.2 kiln fans before and after reconstruction.

8 sets of variable speed drives in different occasions as follows:

From above data we see energy-saving efficiency of each kiln system fan after reconstruction.

Running 24 hours a day, 26 days a month, 11 months a year, that is 7392 hours in all, we can calculate the energy-saving capacity and energy-saving of fans.

Taking the calculation of the fans in line 1 kilns for example:

energy-saving power:

(790-661)+ (774-681)+ (2221-1777)+ (348-247)=767 (kW)

yearly energy-saving:

767kW×7392h=5669600kW·h

yearly energy-saving:

5669600kW·h×0.5yuan/kW·h=2834800 yuan(USD 416882)

2) Comparison table between line1 and line2 fans before and after reconstruction in the Cement plant:

5 sets of variable speed drives in different occasions:

The tightness of cement Kiln is better, so energy-saving effect is good, especially for high-temperature fans. Calculating the energy-saving of fans according to data:in the case of daily production 5500t, the current of no.1 kiln high-temperature fans is about 156A, electric consumption power is about 1430kW, which declines about 490kW. In the case of daily production 5500t, the current of no.2 kiln high-temperature fans is about 148A, electric consumption power is about 1380kW, which decline about 510kW.

Running 24 hours a day, 26 days a month, 11 months a year, that is 7392 hours in all, we can calculate the energy-saving of two sets of high-temperature fans.

High-temperature fans in line 1 kiln:

energy-saving power:1920-1430=490 (kW),yearly energy-saving:

490 kW×7392h=3622000kW·h,yearly energy-saving:3622000kW·h×0.64yuan/kW·h=2318000yuan

High-temperature fans in line 2 kiln:

energy-saving power:1890-1380=510 (kW),yearly energy-saving:

510 kW×7392h=3770000kW·h, yearly energy-saving: 3770000kW·h×0.64yuan/kW·h=2413000yuan (USD 354852)

Another major benefit of variable speed reconstruction is that it increases the production of kiln system nearly by 19%, and it also improves manufacturer procell.

Conclusion

At present, the competition of cement industry is very intense, and the key is still manufacturing costs. Electrical energy consumed by motor accounts for nearly 30% of the cost. Power consumption used to drive fans occupies a large proportion for motor, so declining consumption and improving benefits for motor is much of importance. Nowadays variable speed drive technology is more mature and failure rate is lower. It is an ideal equipment for energy-saving reconstruction in cement plant.

Most of variable speed drives are applying on high temperature fans, kiln head coal mill fans, kiln head surplus fans, raw mill circulating fans and so on. Two production lines with daily productivity 5000T in the Cement factory. By variable speed drive, the two production lines achieve ideal energy-saving effect.

The shortcomings of original hydraulic couplers

- Hydraulic coupler is mechanical adjusting speed equipment. It has 5-8% speed loss. Power loss is converted into heat, so a great mount of cooling water is needed to cool oil.

- The oil temperature is above 95 degree in the actual operation, the water of cooling equipment is easy to scaling and plugging, which results in trouble.

- Because the hydraulic couplers deliver power by hydraulic pressure oil, its speed control is not stable, the power factor and accuracy of speed adjusting is bad.

- Because of the low efficiency of the whole hydraulic couplers, low power factor, inaccuracy of speed adjusting, big speed adjusting loss, a large amount of maintenance and high costs, energy-saving effect is not significant.

Asynchronous motor adjusts speed by changing the supply power frequency of stator to realize variable speed adjusting speed. It can maintain small speed disparity during the process from low speed to high speed, so the small consumption speed disparity power and high efficiency is the most reasonable method of adjusting speed for asynchronous motor.

At present, the variable speed adjusting speed is main adjusting speed method for asynchronous motor; it is widely used in many fields.

Variable speed speed system has many significant advantages as following:

- A lot of expenditure loss caused by load tailgate or valve adjustment will disappear after variable speed drive reconstruction;

- The power factor of asynchronous motor rises from 0.85 to above 0.95 after using variable speed drive;

- The variable speed drive has smallest loss and the efficiency of the whole equipment is 97%;

- Speed adjusting range variable speed drive is from 0 to100%. Speed adjusting range of hydraulic coupler is from 40% to 95%, and it has 5% speed loss at high speed range. This will affect output power of equipment.

- The efficiency of variable speed drive is high in the whole adjusting speed range (more than 96%), but the efficiency of hydraulic coupler decreases with adjusting speed decreasing, this results in a lot of loss. Energy-saving decreases sharply.

- Variable speed drive realizes soft-start for motor. It solves start impact problem thoroughly. If needed, motor can start frequently in a short time. Hydraulic coupler can't solve the start impact problem. Motor still starts directly and needs starting device. It also has big start impact and can't start frequently in a short time.

- When variable speed drive drives motor, the motor only needs to be separated from original switch and electrical connection cable. Then connect it to variable speed drive. It is no need to change connection of motor or change any basic mechanism. When hydraulic coupler puts into service, it must be connected in series with motor and mechanical connection axis. Basic equipment needs to be moved and re-casted. These modifications may be not permitted in some sites.

- The variable speed drive is high-technology equipment with high reliability and free maintenance. Hydraulic coupler is mechanical equipment with oil pipeline, water pipeline and many sets of systems, so it has high failure rate and heavy maintenance, which shortens the effective production time.

Taking variable speed drive on high-temperature fans for example: the production line of daily production 5000t, high-temperature fan motor is equipped with 6kV/2500kW variable speed drive.

According to the load parameters and operation condition provided by cement plant, the variable speed drive (rated voltage is 6kV, rated current is300A) is applicable to the plant.

Kiln-back high-temperature fans system introduction

Cement Production line are hanging with kiln, its circuit system is shown as Fig.1.

Rotary kiln with daily production 5000t has heated steel cylindrical with 4 degree bevel, diameter of 4.8m and length of 74m, various firebrick were inserted in it. Raw materials from pre-heater enter the kiln from the back of kiln. It is mixed and calcined in rotary kiln at high temperature depending on the the kiln rotating, and materials move forward depending on the slope of the kiln and the kiln rotating.

Reconstruction introduction

The power and the heat diffusion of variable speed drive is much. In order to ensure adequate ventilation cooling, we designs wind duct on the top of variable speed drive cabinet and power cabinet respectively. They connect to outlet as a whole, discharging the heat outside, ensuring the reliable ventilation effect.

The statistic of energy saving

We make statistic about the related operation data before and after variable speed drive reconstruction. The part of the data are analyzed and collected as follows:

1) The comparison table between cement no.1 and no.2 kiln fans before and after reconstruction.

8 sets of variable speed drives in different occasions as follows:

| Applied occasions | Motor power (kW) | Motor power before reconstruction (kW) | Motor power after reconstruction (kW) |

| Line 1 no.1 circulating fans | 1000 | 790 | 661 |

| Line 1 no.2 circulating fans | 1000 | 774 | 681 |

| Line 1 high-temperature fans | 2500 | 2221 | 1777 |

| Line 1 coal mill fans | 630 | 348 | 247 |

| Line 2 no.3 circulating fans | 1000 | 830 | 681 |

| Line 2 no.4 circulating fans | 1000 | 780 | 632 |

| Line2 high-temperature fans | 2500 | 2420 | 1866 |

| Line 2 coal mill fans | 630 | 388 | 257 |

From above data we see energy-saving efficiency of each kiln system fan after reconstruction.

Running 24 hours a day, 26 days a month, 11 months a year, that is 7392 hours in all, we can calculate the energy-saving capacity and energy-saving of fans.

Taking the calculation of the fans in line 1 kilns for example:

energy-saving power:

(790-661)+ (774-681)+ (2221-1777)+ (348-247)=767 (kW)

yearly energy-saving:

767kW×7392h=5669600kW·h

yearly energy-saving:

5669600kW·h×0.5yuan/kW·h=2834800 yuan(USD 416882)

2) Comparison table between line1 and line2 fans before and after reconstruction in the Cement plant:

5 sets of variable speed drives in different occasions:

| Applied occasions | Motor power | Motor power before reconstruction | Motor power after reconstruction |

| Line 1 high-temperature fans | 2500KW | 1920 | 1430 |

| Line 1 surplus fans | 630KW | 455 | 345 |

| Line 2 high-temperature fans | 2500KW | 1890 | 1380 |

| Line 2 coal mill fans | 630KW | 510 | 430 |

| Line 2 surplus fans | 630KW | 425 | 330 |

The tightness of cement Kiln is better, so energy-saving effect is good, especially for high-temperature fans. Calculating the energy-saving of fans according to data:in the case of daily production 5500t, the current of no.1 kiln high-temperature fans is about 156A, electric consumption power is about 1430kW, which declines about 490kW. In the case of daily production 5500t, the current of no.2 kiln high-temperature fans is about 148A, electric consumption power is about 1380kW, which decline about 510kW.

Running 24 hours a day, 26 days a month, 11 months a year, that is 7392 hours in all, we can calculate the energy-saving of two sets of high-temperature fans.

High-temperature fans in line 1 kiln:

energy-saving power:1920-1430=490 (kW),yearly energy-saving:

490 kW×7392h=3622000kW·h,yearly energy-saving:3622000kW·h×0.64yuan/kW·h=2318000yuan

High-temperature fans in line 2 kiln:

energy-saving power:1890-1380=510 (kW),yearly energy-saving:

510 kW×7392h=3770000kW·h, yearly energy-saving: 3770000kW·h×0.64yuan/kW·h=2413000yuan (USD 354852)

Another major benefit of variable speed reconstruction is that it increases the production of kiln system nearly by 19%, and it also improves manufacturer procell.

Conclusion

At present, the competition of cement industry is very intense, and the key is still manufacturing costs. Electrical energy consumed by motor accounts for nearly 30% of the cost. Power consumption used to drive fans occupies a large proportion for motor, so declining consumption and improving benefits for motor is much of importance. Nowadays variable speed drive technology is more mature and failure rate is lower. It is an ideal equipment for energy-saving reconstruction in cement plant.

You may also like:

The good of PLC is it work in a hazard environment and robust. We have

Omron CQM1 for DI water plant, after a big flooding in Thailand ( stay

under water for more than 2 months) after we clean dry and bake ...

1a. if the driver is a synchronous motor there isn't a power factor problem as the motor will be either 1.0 or leading PF

1b. if the driver is induction: check with the motor manufacturer for the power ...

From an amplifier design standpoint, the Safe Torque Off (STO) is redundant with the enable input to the amplifier. I'm not sure what "problem" this STO requirement is trying to solve that the enable/disable ...

Clean the variable frequency drive heatsink and check or replace the fans. I like new fans every five years. I also double check the drives installation. This is a good opportunity to make corrections to the ...

Altitude Standard motors are designed to operate below 3300 feet. Air is thinner and heat is not dissipated as quickly above 3300 feet. Most motors must be derated for altitude. The following chart gives ...

VSD blog: A deep observation of automation control industry, especially in AC motor variable speed drive for industrial motor controls.

VSD blog: A deep observation of automation control industry, especially in AC motor variable speed drive for industrial motor controls. Hot Tags

Featured

7 months back I was involved in a harmonics evaluation study at Budweiser. This was one of many I've participated in over the past 20 years, basically because in facilities like ...

Most of variable speed drives are applying on high temperature fans, kiln head coal mill fans, kiln head surplus fans, raw mill circulating fans and so on. Two production lines ...

Variable speed drive application in purification system optimizes the system performance, improves purification effect, reduces power consumption greatly. According to related ...

The motor power factor does not make a big difference other than giving an idea of loading. In regards to the variable speed drive fixing power factor everyone is mostly correct. ...

A soft starter is a basic device which will ramp up the speed of your motor to full speed over a preset time, easing mechanical stress and also easing the high inrush currents ...

What's New

Variable Speed Drive Harmonics

Variable speed drive energy saving in cement industry

PLC and DAQ

Is it good to do preventive maintenance for variable speed drives

Does motor starts number affect motor life?

Variable speed drive for ID Fans in mining industry

Regenerative power frequency back to line power

Variable speed drive for axial-flow fans

Variable speed drive energy saving in cement industry

PLC and DAQ

Is it good to do preventive maintenance for variable speed drives

Does motor starts number affect motor life?

Variable speed drive for ID Fans in mining industry

Regenerative power frequency back to line power

Variable speed drive for axial-flow fans