Home » Blog » Applications » Variable speed drive for axial-flow fans

Variable speed drive for axial-flow fans

Because of complicated production conditions and environment affection, equipments working in mine are usually big model. Motor always runs in full speed. "big horse pulling small carriage" is not unusual. Energy wasting is serious. How to reduce production cost and heighten efficiency by technology innovation is an urgent problem for coal companies.

Contra-rotating axial-flow fan is backbone of breath system in mine. It works in 24 hours continuously. With digging and exploring extending, lane prolongs and air flow demand increases continuously. Fan power should increase. Air flow demand also requires to be adjusted due to seasons come and go. But power of motor and fan in coal mine is usually far more than operation power of normal production.

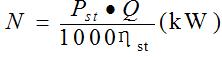

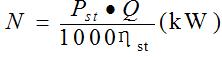

Motor model is designed as per the most inferior stage. Generally, design motor power as per actual air flow parameter, calculation is following:

N-motor power(kW);

Pst-resistance in most inferior stage(Pa) ;

Q-total air flow in most inferior stage(m3/s);

ηst-actual efficiency;

K-power margin, usually it is K=1.1~1.15

Conventionally, air flow is adjusted by adjustment damper or valve opening. There are following problems in terms of fan model and production state.

Characters of contra-rotating axial flow fan

Install an impeller behind of another but rotating direction of impellers is opposite. We call it contra-rotating axial-flow fan. Two levels of impellers are contra-position and they are driven by same model motors. First level impeller rotates clockwise and the second level impeller rotates anticlockwise. Entering the first impeller, air gets energy and then air is discharged through the second impeller. Second impeller also plays role of fixed blade, gets speed flow in circle direction, increases flow energy, thereby reaching high efficiency and high pressure.

Contra-rotating axial flow fan reform with variable speed drive

The fan is very important for production safety. Gas explosion has a direct relation with adequate ventilation in lane. Once ventilation is not smooth, gas density rising leads to explosion, causing serious accident and endangering workers' life. If such important equipment trips off due to fault, it will threatens whole mine safety heavily. Therefore, variable speed drive which drives equipment must be reliable.

Conclusion

Variable speed drive realizes soft start/stop and saves energy. It adjusts speed according to air flow demand in lane easily with ideal effect. China has many coal mines, medium voltage variable speed drive application must be widely in this field.

Variable speed drive reform

Contra-rotating axial-flow fan is backbone of breath system in mine. It works in 24 hours continuously. With digging and exploring extending, lane prolongs and air flow demand increases continuously. Fan power should increase. Air flow demand also requires to be adjusted due to seasons come and go. But power of motor and fan in coal mine is usually far more than operation power of normal production.

Motor model is designed as per the most inferior stage. Generally, design motor power as per actual air flow parameter, calculation is following:

N-motor power(kW);

Pst-resistance in most inferior stage(Pa) ;

Q-total air flow in most inferior stage(m3/s);

ηst-actual efficiency;

K-power margin, usually it is K=1.1~1.15

Conventionally, air flow is adjusted by adjustment damper or valve opening. There are following problems in terms of fan model and production state.

- Serious waste: Fan model is designed with big redundancy, but it works in light load mostly. Damper adjustment causes serious energy waste and cost rising.

- Difficult start-up and serious mechanical damage: Time of direct start is long and start current is big, which threatens motor insulation. Single shaft torque makes fan cause big vibration force, thereby affecting lifetime of motor, fan and other equipments.

- Low automatization level: Damper adjustment has no function of instant auto-adjustment. In the case of fault, such as flow short circuit, it will affect production badly.

Characters of contra-rotating axial flow fan

Install an impeller behind of another but rotating direction of impellers is opposite. We call it contra-rotating axial-flow fan. Two levels of impellers are contra-position and they are driven by same model motors. First level impeller rotates clockwise and the second level impeller rotates anticlockwise. Entering the first impeller, air gets energy and then air is discharged through the second impeller. Second impeller also plays role of fixed blade, gets speed flow in circle direction, increases flow energy, thereby reaching high efficiency and high pressure.

Contra-rotating axial flow fan reform with variable speed drive

The fan is very important for production safety. Gas explosion has a direct relation with adequate ventilation in lane. Once ventilation is not smooth, gas density rising leads to explosion, causing serious accident and endangering workers' life. If such important equipment trips off due to fault, it will threatens whole mine safety heavily. Therefore, variable speed drive which drives equipment must be reliable.

Variable speed drive application benefits:

- No impact on power grid. Because variable speed drive realizes soft start, it avoids current impact and reduces impact on power grid. It can start/stop at any time, indicating its soft starter function.

- Air flow is controlled by variable speed. Adjustment range is 0~100%. So it can adjust air flow as per production requirement.

- Much energy is saved. In variable speed drive control, fan does not need to run in full load. Energy saving rate can reach 63% or more.

- Variable speed drive lowers work labour and prolongs equipment lifetime. In variable speed drive control, fan runs in low speed in most time, which lowers mechanical intensity and electrical impact greatly.

- Variable speed drive reform makes motor connect to fan directly, reducing cost of driving parts.

- Speed decreasing improves lubricaing state, so fault of drive lowers.

- Pressure lowering relieves pipe seal, prolonging lifetime.

- Completed monitor and high reliability heighten efficiency and reduce maintenance labour.

- After reform with variable speed drive, during operation, two motors are required to keep same frequency, thereby reaching same speed. That one runs in low speed and the other runs in high speed should be avoided, otherwise air resistance creates, affecting fan normal operation.

Conclusion

Variable speed drive realizes soft start/stop and saves energy. It adjusts speed according to air flow demand in lane easily with ideal effect. China has many coal mines, medium voltage variable speed drive application must be widely in this field.

You may also like:

The real facts which determine the usability of anti-friction or sleeve bearings: low coast over a long period; cheaper periodic maintenance and/or reduced noise. Another important reason for the application ...

The SCADA (Supervisory Control And Data Acquisition) would also be a HMI (Human Machine Interface) and if the HMI system had the additional data acquisition which most are capable of then it would also be ...

A soft starter is a basic device which will ramp up the speed of your motor to full speed over a preset time, easing mechanical stress and also easing the high inrush currents which can be experienced by ...

Control circuit provides control signal to the asynchronous motor power supply (voltage and frequency adjustable) main circuit, which has the arithmetic circuit of frequency and voltage, the voltage and ...

It is possible to power a three phase motor from a single phase power supply and using a capacitor bank to create the rotating magnetic field. Basically the capacitor banks ensures that there is a phase ...

VSD blog: A deep observation of automation control industry, especially in AC motor variable speed drive for industrial motor controls.

VSD blog: A deep observation of automation control industry, especially in AC motor variable speed drive for industrial motor controls. Hot Tags

Featured

7 months back I was involved in a harmonics evaluation study at Budweiser. This was one of many I've participated in over the past 20 years, basically because in facilities like ...

Most of variable speed drives are applying on high temperature fans, kiln head coal mill fans, kiln head surplus fans, raw mill circulating fans and so on. Two production lines ...

Variable speed drive application in purification system optimizes the system performance, improves purification effect, reduces power consumption greatly. According to related ...

The motor power factor does not make a big difference other than giving an idea of loading. In regards to the variable speed drive fixing power factor everyone is mostly correct. ...

A soft starter is a basic device which will ramp up the speed of your motor to full speed over a preset time, easing mechanical stress and also easing the high inrush currents ...

What's New

Variable Speed Drive Harmonics

Variable speed drive energy saving in cement industry

PLC and DAQ

Is it good to do preventive maintenance for variable speed drives

Does motor starts number affect motor life?

Variable speed drive for ID Fans in mining industry

Regenerative power frequency back to line power

Variable speed drive for axial-flow fans

Variable speed drive energy saving in cement industry

PLC and DAQ

Is it good to do preventive maintenance for variable speed drives

Does motor starts number affect motor life?

Variable speed drive for ID Fans in mining industry

Regenerative power frequency back to line power

Variable speed drive for axial-flow fans